- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2023-11-01 Origin: Site

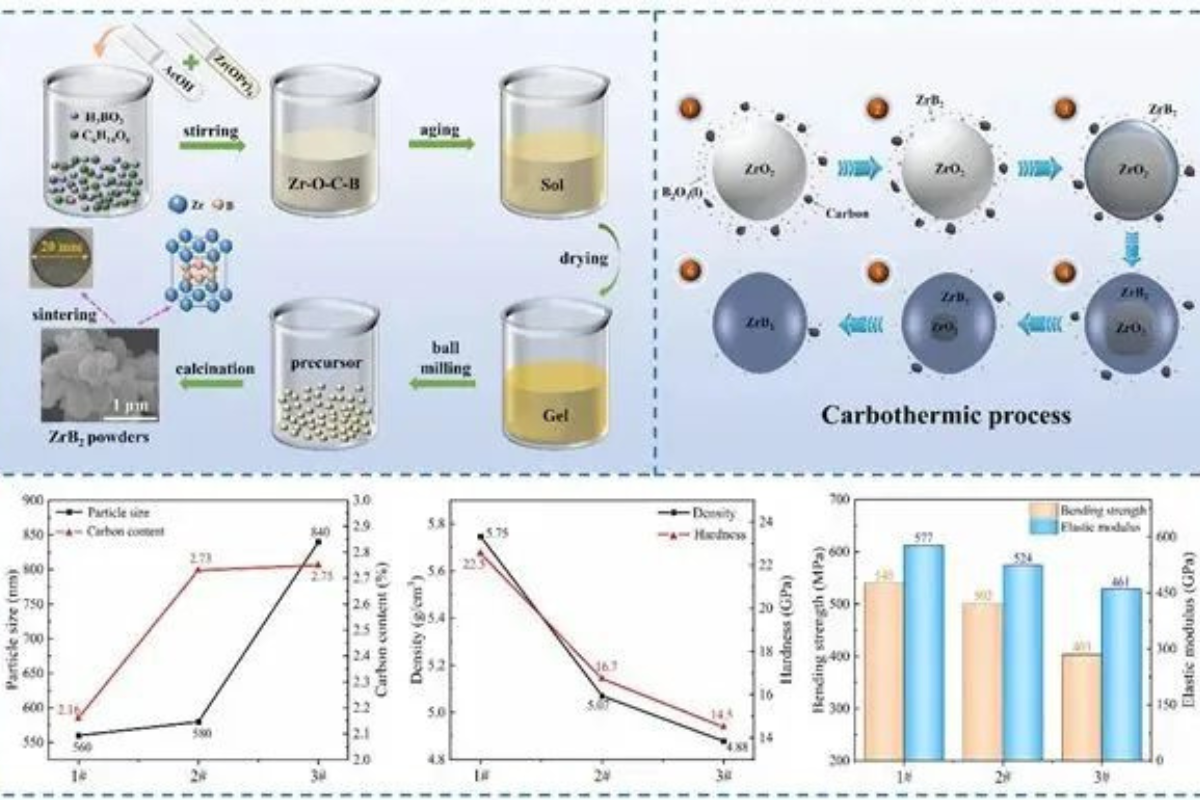

Recently, the team of researcher Li Yue from Institute of Solid State, Hefei Institute of Materials, Chinese Academy of Sciences (CAS), in cooperation with the team of Prof. Zhang Xinghong from Harbin Institute of Technology (HIT), has made a new progress in the preparation of ultrafine, high purity and ultrahigh-temperature ceramic powders and mechanism research, and has developed a new process of liquid-phase ceramic precursor-carbon/boron thermal reduction, which can realize the preparation of a variety of high-purity, ultrafine boride ceramic powders in batch. The results have been published in the Journal of Materials Science & Technology and ACS Applied Engineering Materials.

Boride ultrahigh-temperature ceramics and their composites have become important candidates for space vehicles in extreme thermal environments due to their excellent comprehensive physical and chemical properties. Among them, ZrB2 and HfB2 have received widespread attention due to their extremely high melting points (over 3000°C), high oxidation resistance and excellent corrosion resistance.

The key to developing high-performance boride ceramic materials is to obtain high-performance ceramic powders. Generally speaking, ceramic powders with ultra-fine particle size, high purity and low oxygen content are not only conducive to the densification of the block during the low-temperature sintering process, but also avoid the damage to the ceramic matrix composites matrix, thus enhancing the oxidation resistance and mechanical properties of the ceramic matrix composites. Traditional methods such as mechanized alloying and high-temperature self-propagation are difficult to obtain boride ceramic powders with both high purity and ultrafine particle size. Therefore, there is an urgent need to develop a new process to realize the engineering preparation of high purity and ultrafine particle size boride ceramic powders, which can provide raw materials for the improvement of boride ceramic matrix composites.

To this end, the Solid State Institute of ceramic powder research team after a long period of research, developed a liquid-phase precursor - carbon / boron thermal reduction process route, the successful preparation of IV-VI group transition metal unit / multivariate / medium-high entropy ceramic powders, and to achieve high purity and ultrafine ZrB2, HfB2 ceramic powders prepared by the engineering of ceramic powders.

Facerom, as a thermal equipment supplier in the field of advanced ceramics, is committed to providing more reliable furnace solutions for the world.